|

KENOS Hardware Technology Co., Ltd.

|

Zamak die casting professional manufacturer

| Payment Terms: | T/T,L/C,D/A,D/P,WU |

| Place of Origin: | Guangdong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Zamak die casting:

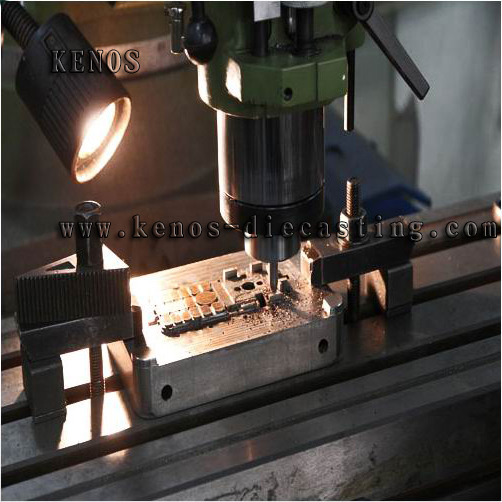

Main process: Die casting,deburring,hole drilling,tapping,polishing,plating,inspecting,packaging.

Zamak die casting professional manufacturer

Dongguan KENOS Hardware Technology Co., Ltd. is a die casting manufacturers set of die casting mold design, mold manufacturing, zinc, aluminum, alloy die casting in one. A full set of production process is perfect, advantageous to ensure the quality of products, on time delivery.

Our main technical staff have a wealth of production experience in the design and process of die casting mold. At the same time, the implementation of strict quality detection, fast delivery, dedicated service, preferential price, guaranteed to provide customers with high quality products. Looking for die casting manufacturers, KENOS is your most wise choice.

The current scope of business: magnesium die casting, zinc and Zamak die casting, aluminum die casting, aluminum stamping and stainless steel stamping. xinniusongtg

Dongguan songshun mould steel CO.,LTD.

songshun Zamak die casting Tel: +86-769-85475596

songshun Zamak die casting Fax: +86-769-82285809

songshun Zamak die casting Contact E-mail: admin@songshunsteel.com

songshun Zamak die casting website: http://www.songshunsteel.com/

songshun Zamak die casting Address: No.4 Dongda Street, ShaTou, Chang'an Town, Dongguan City, Guangdong Province,China

songshun Zamak die casting Zip: 523850

About Our Product:

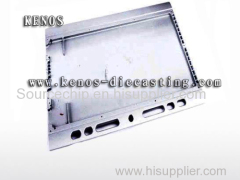

1)material type: mainly magnesium and zinc alloy with SGS certification

2)Product tolerance: according to customer's requirement and decided by the mold

3)Main products:die casting parts,die casting accessories,die casting components, including phone shell,automotive parts,computer parts,PC parts,bicycle parts,camera parts,housing,parts,gears,diy tools,optical components,engine components,pump components,furniture,fittings,etc

4)Related industry: computer,cellphone,communication,LED,automotive,Camera,optical,etc

5)Main process: Die casting,deburring,hole drilling,tapping,polishing,plating,inspecting,packaging

6)Product making equipment:

1. 2 sets of die casting machine (hot chamber)

2. 8 sets of punch press

3. 3 sets of hole-punching machine

4. 15 sets of tapping machine

5. 2 sets of CNC machine

7)surface finish :Zinc plating,Chrome plating,Trivalent chrome plating,Powder coating,Painting,E-Coating,Phosphating,Anodizing,etc

About Our Mould :

1)Mold type: die casting mold as customer's drawing or sample

2)Mold tolerance:generally within ±0.03mm

3)Mold size:either small or big are available according to product,generally length from 100mm to 1 meter

4)Mold making process:milling,grinding,wire cutting,CNC,EDM,etc

5)Mold making equipment:

1. eight sets of milling machine

2.three sets of grinder

3. two sets of wire cutting machine

4. one set of CNC machine

5. five sets of EDM machine

6)Mould life:Over 1000,000 shots,lifetime free for maintaining the mould

7)Drawing type:PDF,DWG,IGS,STP,STEP,PRT are all acceptable

Our main advantage:

1)specialize in magnesium and zinc die casting for 10 years

2)Green products with many international certification

3)Good quality products with competitive price

4)Best after-sale service

5)One stop service to solve all of your problems

6)Always on service for you during your working time

7)Quotation will be sent within 24 hours any time

8)Always on service for you during your working time

9)Samples could be provided for customer's trail and test. Once not meet customer's need, we will modify the mold until customer's satisfactory.